As we know that hydraulic elevators are still in use, even though usually we use and talk about traction elevators.

In this blog let’s discuss the differences between them.

Operational Mechanism

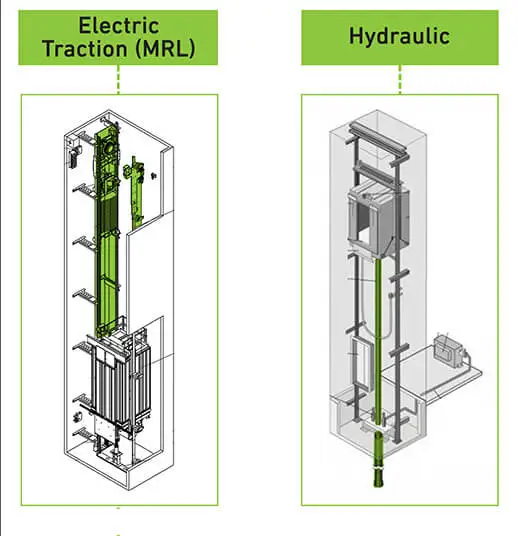

- Traction Elevators: These elevators use a motor-driven sheave (a pulley) to move the elevator car up and down. The car is attached to steel ropes or belts, which are looped around the sheave. As the sheave turns, the ropes move, pulling the car either up or down. Traction elevators can be geared or gearless, with gearless types often found in high-rise buildings due to their ability to reach greater speeds.

- Hydraulic Elevators: Unlike traction systems, hydraulic elevators rely on a piston and cylinder mechanism. The car is lifted by pushing oil into the cylinder, which moves the piston upward. To descend, the fluid is released from the cylinder, allowing the car to lower by gravity. Hydraulic elevators are typically used in low to mid-rise buildings (up to 5-6 floors) due to their limited speed and height capabilities.

Energy Efficiency

- Traction Elevators: Traction systems, especially modern machine-room-less (MRL) models, are generally more energy-efficient than hydraulic elevators. They use counterweights to balance the load, reducing the motor’s energy consumption. Additionally, regenerative drives can further enhance efficiency by converting braking energy back into usable power.

- Hydraulic Elevators: These elevators tend to be less energy-efficient, as the pump motor must lift the car against gravity without the aid of counterweights. While they consume less energy during descent, overall energy usage is higher, especially in busy buildings with frequent trips.

Installation and Maintenance Costs

- Traction Elevators: Traction elevators often require a dedicated machine room, especially for traditional models. However, newer MRL designs eliminate this need, reducing space and installation costs. Traction elevators generally have higher initial installation costs, but their longer lifespan and energy efficiency can offset this over time. Maintenance is also typically more complex and expensive due to the sophisticated machinery.

- Hydraulic Elevators: Hydraulic systems are usually less expensive to install due to simpler machinery and fewer components. They do not require a machine room, but they need a space for the hydraulic fluid tank. Maintenance costs are typically lower, although the hydraulic fluid needs to be regularly checked and replaced. However, hydraulic elevators have a shorter lifespan compared to traction elevators, and the environmental impact of potential fluid leaks must be considered.

Performance and Ride Quality

- Traction Elevators: Traction elevators offer superior ride quality, especially at higher speeds, making them ideal for taller buildings. The smoothness of the ride, reduced noise levels, and quick acceleration and deceleration contribute to a more comfortable passenger experience.

- Hydraulic Elevators: Hydraulic elevators are slower and provide a less smooth ride, particularly as they age. They are best suited for low-rise buildings where speed and ride quality are less critical. However, they are known for their strong lifting capacity, making them suitable for transporting heavy loads.

Building Requirements

- Traction Elevators: These elevators are versatile and can be used in both low and high-rise buildings. They are the go-to choice for skyscrapers and high-speed applications. The requirement for a machine room or MRL space is a consideration, as is the structural integrity needed to support the hoisting machinery.

- Hydraulic Elevators: Best suited for low to mid-rise buildings, hydraulic elevators are ideal for structures where space is limited or where the budget does not allow for the higher cost of a traction system. However, their height limitation makes them unsuitable for taller buildings.

Conclusion

Choosing between a traction and hydraulic elevator depends on several factors, including building height, budget, energy efficiency, and intended use. Traction elevators are typically preferred for high-rise buildings and applications requiring speed and efficiency, while hydraulic elevators are a cost-effective solution for low-rise buildings with moderate traffic. Understanding these differences can help you select the elevator system that best meets your project’s needs.