Elevator Traction Ratio: Key to Safety and Efficiency

Elevator traction ratio plays a pivotal role in the world of vertical transportation. It’s a fundamental concept that impacts the safety, efficiency, and performance of elevators. This blog post will delve deep into the intricacies of elevator traction ratio, exploring its definition, importance, factors affecting it, and how it’s calculated. Whether you’re an elevator professional, an engineer, or simply curious about how elevators work, this article will provide valuable insights.

What is Elevator Traction Ratio?

The elevator traction ratio is the ratio of the speed of the elevator car to the speed of the hoisting machine’s output shaft. In simpler terms, it determines how many times the hoisting machine has to rotate to move the elevator car a certain distance. This ratio is crucial as it directly affects the elevator’s speed, acceleration, and deceleration capabilities. A higher traction ratio means the elevator can move faster, while a lower ratio results in slower movement.

1. Safety First

— The traction ratio is a key factor in ensuring the safety of elevator operations. It helps in maintaining the proper tension in the hoisting ropes. If the traction ratio is not correctly set, there could be issues such as rope slippage, which can lead to dangerous situations. For example, in high – rise buildings, a malfunctioning traction ratio could cause the elevator to lose control during ascent or descent.

— According to safety standards, the traction ratio must be designed in such a way that the elevator can safely carry its rated load and handle emergency situations, like sudden stops or power failures.

2. Efficiency and Performance

— An optimized traction ratio improves the overall efficiency of the elevator system. It reduces the energy consumption of the hoisting machine. When the traction ratio is well – tuned, the motor doesn’t have to work as hard to move the elevator car, resulting in lower electricity bills and less wear and tear on the equipment.

— In terms of performance, the right traction ratio ensures smooth acceleration and deceleration. This is crucial for passenger comfort. No one wants to experience a jerky start or stop when using an elevator. A well – designed traction ratio provides a seamless ride, making the elevator a more pleasant mode of transportation.

Factors Affecting Elevator Traction Ratio

1. Load Capacity

— The weight that an elevator is designed to carry has a significant impact on the traction ratio. Heavier loads require a different traction ratio compared to lighter ones. For example, a freight elevator that needs to transport heavy machinery will have a different traction ratio than a passenger elevator in a residential building. The higher the load capacity, the more torque the hoisting machine needs to generate, which may require adjustments to the traction ratio.

2. Building Height

— Taller buildings pose different challenges for elevator systems. As the height increases, the length of the hoisting ropes also increases, which can affect the tension and the overall mechanical performance. In high – rise buildings, a higher traction ratio may be required to ensure that the elevator can reach the upper floors in a reasonable time. For instance, in a 100 – story building, the elevator needs to be fast enough to serve the occupants efficiently, and the traction ratio is adjusted accordingly.

3. Type of Hoisting Machine

— Different types of hoisting machines, such as geared and gearless motors, have varying characteristics that influence the traction ratio. Geared motors are often used in low – to – medium – speed elevators and may require a different traction ratio compared to gearless motors, which are more commonly used in high – speed elevators. The efficiency and torque output of the hoisting machine play a role in determining the optimal traction ratio.

Calculating Elevator Traction Ratio

The calculation of the elevator traction ratio involves several parameters. The basic formula for calculating the traction ratio (TR

) is:

TR=v_car / v_motor

where v_car is the speed of the elevator car and v_motor is the speed of the motor’s output shaft.

However, in a more complex scenario, other factors such as the number of rope wraps around the sheave, the diameter of the sheave, and the gear ratio of the hoisting machine need to be considered. For example, if there are multiple rope wraps around the sheave, the effective traction ratio will change. The formula then becomes more elaborate, taking into account these additional variables.

Real – World Examples of Traction Ratio in Action

1. Residential Elevators

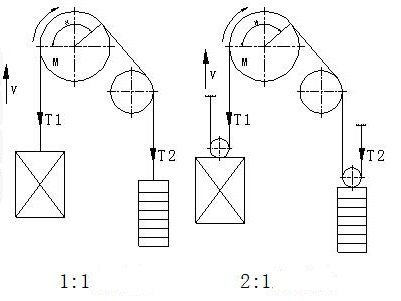

— In a typical residential building with 5 – 10 floors, the elevator is designed to serve a relatively small number of passengers. The load capacity is usually around 800 – 1000 kg. For such elevators, a traction ratio of 1:1 or 2:1 is commonly used. A 1:1 traction ratio means that for every rotation of the hoisting machine’s output shaft, the elevator car moves the same distance as the circumference of the sheave. This type of ratio provides a simple and cost – effective solution for low – rise residential buildings.

2. High – Rise Office Buildings

— In a high – rise office building, the elevator needs to be fast and efficient to handle a large number of passengers during peak hours. For example, in a 50 – story office building, the elevator may have a load capacity of 1600 – 2000 kg and a high – speed gearless hoisting machine. A traction ratio of 4:1 or even higher may be used to achieve the required speed. This allows the elevator to quickly transport passengers to their desired floors, reducing waiting times and improving overall building efficiency.

Future Trends in Elevator Traction Ratio Technology

1. Smart Elevator Systems

— With the advancement of technology, smart elevator systems are becoming more prevalent. These systems can adjust the traction ratio in real – time based on factors such as the number of passengers, the time of day, and the building’s energy consumption requirements. For example, during off – peak hours, the elevator may adjust to a lower traction ratio to save energy, while during peak hours, it can increase the ratio to improve service speed.

2. Sustainable Elevator Design

— As the world moves towards more sustainable practices, elevator manufacturers are focusing on developing systems that are more energy – efficient. This includes optimizing the traction ratio to reduce energy consumption. New materials and design techniques are being explored to create lighter yet stronger hoisting ropes and sheaves, which can further improve the traction ratio and overall elevator performance.

In conclusion, elevator traction ratio is a critical aspect of elevator design and operation. It impacts safety, efficiency, and performance, and understanding it is essential for anyone involved in the elevator industry. By considering factors such as load capacity, building height, and hoisting machine type, and by staying updated on future trends, we can ensure that elevators continue to provide safe and efficient vertical transportation.